7 Simple Ways to Practice Sewing Straight Line Stitches Straight line stitching How many times have…

Choosing Fabrics for Custom Tailoring

CHOOSING FABRICS FOR CUSTOM TAILORING

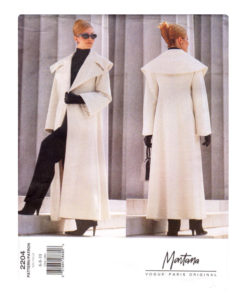

Choosing fabrics for custom tailoring is a detailed process of selecting a combination of appropriate fabrics that respond best in tailoring. Custom tailoring involves the use of several different fabrics including the outer fashion fabric, interfacing, underlining, lining and other required notions. Unlike dressmaking, you will likely invest more money, time, skill and effort, in tailoring a custom coat or jacket. Therefore, your next step after selecting an appropriate pattern should be choosing all of the fabrics and notions needed to construct your tailored garment.

Fashion fabric or the outer garment fabric used for custom tailoring should be of a fairly simple weave with tightly woven yarns. You should first review the fabric recommendations on the back of the pattern envelope with the design details of each view. All commercial patterns clearly state what type of fabric may be used, as well as any other pertinent buying information for each design.

SELECTING QUALITY WOOL FABRICS

Although custom tailoring methods can be adapted to a variety of fabrics, woven fabrics of good quality wool are most suitable and are traditionally used for tailoring. Most woven wool fabrics for tailoring are either plain or twill weave. Wool tailors well; it is easy to shape, crease, shrink, and stretch with steam. Wool absorbs moisture better than any other natural fiber. It can absorb up to 30 percent of its weight without feeling wet.

100% Wool Fabrics for Custom Tailoring

Wool is a fiber from the fleece of certain animals. Most wool comes from sheep or lambs. Hair from some goat and camel species is also called wool. Each tiny wool fiber has a very complex structure which even textile scientists do not fully understand. This structure gives wool fibers a combination of properties not found in other fibers. It is these fiber properties that give wool fabrics the characteristics needed for tailoring.

- Wool resists abrasion during wear

- Wool is flexible and can bend many times without breaking

- Fiber flexibility makes wool fabrics durable

- Wool fibers shed wrinkles, keep their shape and can be eased and stretched in the tailoring process

- Wool traps air, insulates; making wool fabrics warm to wear

- Wools shorten and mats when agitation, moisture or heat is applied called felting (ask me how I know; once had a beautiful wool knit dress that shrank when washed)

- Wools usually have to be dry cleaned

- Shrink-resistant finishes can be applied; read the labels

- Wool fibers can be stretched up to 30 percent of their length before breaking, if not broken the fibers will return to their normal length when the tension is released

- A garment of good quality wool fabric will not stretch or bag objectionably when worn, unless the garment is fitted too tightly.

Wool has all the characteristics that can withstand the tailoring process of careful stitching, and extreme pressing involved to shape and mold the garment. This results in a completed suit or coat that looks good and keeps its shape when worn. If possible, tailoring skills should be learned on fabrics of this type.

I had a variety of 100% wool fabrics in the white/cream color family, to choose from at FabricMartFabrics.com

Blended Wool Fabrics For Custom Tailoring

Blended wool fabrics for tailoring are made combining a suitable synthetic fiber or silk with wool before spinning into yarn. Often only the label reveals the presence of the other fiber or fibers. Blends are selected on the same basis as 100% wool fabrics, but they may differ in care and performance.

Polyester/wool blends have excellent wrinkle and abrasion resistance and can be permanently pleated. Nylon/wool blends are lighter in weight and have the hand of 100% wool. They wear well and have good resilience, shape retention, and wrinkle recovery. Acrylic/wool blends lack the shape retention of polyester and nylon blends, but may be satisfactory if used as woolens. Silk/wool blends have the tailoring qualities of wool fabrics.

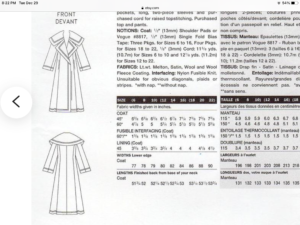

Sometimes it’s difficult to tell the wrong side from the right side, but wool fabrics are folded with right sides together. They range from 50” to 72” wide. The pattern envelope is the best guide in determining how much fabric is needed. If the fabric is purchased before the pattern is selected, the requirements of a similar garment can be used as a guide. Use a conversion chart if the fabric varies in width from that on the pattern envelope.

CHOOSING THE HIDDEN INNER FABRICS

In addition to the outer fashion fabric, the interfacing and underlining are the hidden fabrics that will help your garment retain it’s shape and wear longer. The interfacing is an additional layer of fabric placed between the outer fabric and the facing or hem, In lining a garment, the designer uses only fabric that will comply with the drape of the style and will be attractive, comfortable and smooth.

Interfacing Fabrics For Custom Tailoring

A custom tailored coat or jacket is all about the interfacing. The primary reason for using interfacing is to add support, body and shape, or to eliminate stretching. It is necessary to prevent sagging at the necklines and buttonhole closures, support for the shoulder, front and armhole edges. It also adds softness to hemlines and wrinkle resistance to entire garments or garment sections. Interfacing also protects your fashion fabric from producing ridges along seam allowances and darts during cleaning and pressing.

Interfacing is also needed to stabilize and emphasize details, such as collars, cuffs, pockets, vents, and welts. The built-in shaping and support is its outward shining glory, but is dependent upon the proper use of the right kind of interfacing.

The best quality interfacing used for custom tailoring is hair canvas that’s woven with wool and goat’s hair. The goat hair in hair canvas allows you to create soft, uncreased rolls which will last for the life of the garment. The quality of hair canvasses varies, depending on the fiber content. Hair canvas with large amounts of wool and goat hair are easier to shape, better quality, and more expensive.

Hair Canvas Interfacing for Custom Tailoring

I originally purchased hair canvas interfacing at Wawak.com, because I wanted the best value for my money and thought 5 yards for $40.75 was a good price. However, it was only 20″ wide and a blend, made of 42% cotton, 35% rayon, 17% hair and 6% wool. Additionally, it was fusible. Although, the description states it’s a natural color as appears in the first image below, but what I actually received is what’s shown in the second image and was much too dark for the off-white garment fabric I’m using.

After obtaining more information about the quality of hair canvas interfacing that only contained wool and goat hair, I decided to use all natural fibers with the 100% wool garment fabric being used. However, I could only find hair canvas interfacing with 100% wool and goat hair at two online stores; all others were blended with cotton and synthetics of nylon, polyester, rayon, nylon or viscose.

- VogueFabricStore.com, 60% wool, 40% goat hair; 63” wide, $23.99/yd

- BBlackandSons.com, 60% wool, 40% goat hair; 66” wide, $24.50/yd

Blended Hair Canvas Interfacing For Custom Tailoring

Hair canvas with cotton or synthetic content does not shape as well as wool does, and is less desirable for tailoring. These blends that contain cotton, rayon, or polyester can also shrink inside the garment if subjected to laundry or steam-heat.

Be aware that hair canvas is sold as sew-in and fusible. Fusible interfacings are less suitable for wool fabrics since they do not permit the shaping necessary for tailoring. The adhesive in fusible interfacings is activated when heat and pressure is applied. This adhesive adds stiffness to the fabric which defeats the entire custom tailoring process, but there is a method that uses fusible interfacing.

If separate interfacing pattern pieces are not included with your pattern, you will need to adapt your existing pattern pieces. Except for armholes, eliminate all seam allowances, including style seaming details.

For light-colored and white fabrics, the interfacing must be light in color or white to avoid show-through. In some cases, underlining the interfaced areas is necessary to avoid a color line. Interfacing should be preshrunk along with the wool fabric.

Underlining Fabrics For Custom Tailoring

An underlining is a specially selected fabric used to back parts of the garment not interfaced. It prevents stretching and provides a foundation for hand sewing so that the stitches do not show through on the outside of the garment. It also provides a place to mark construction lines, and makes partial bac and reinforcing of pocket, gusset and other areas unnecessary. Underlining sometimes necessary to prevent construction details from showing on the right side of the garment.

Underlining a jacket or coat is often overlooked in tailoring, yet it is essential to the professional look. If the entire garment is not underlined, at least the upper back should be.

Underlining fabric must be soft and pliable so that it does not interfere with the tailoring process. For a coat or jacket, the best underlining is a preshrunk cotton batiste, sometimes called cotton sheath liner. Other suitable underlining fabrics for custom tailoring are voile, cotton lawn, silk organza, muslin, lightweight linen, an broadcloth. Unless the underlining is guaranteed to shrink less than one percent, it should be laundered and steam pressed before cutting.

The underlining I’m using is 100% Telio Cotton Voile, in Ivory for $6.26/yd, 56″ wide from Fabric.com before they closed the business.

Lining Fabrics For Custom Tailoring

A lining is essentially a duplicate garment made of suitable fabric, completely assembled, then sewn into the garment. It covers the inside of the garment to conceal raw seam edges and to reduce friction when putting on a garment. Linings are always lightweight with a smooth surface to make it easy to slide on over other clothes.

Linings will give your coat or jacket a finished look and make it comfortable to wear. The lining fabric should never shrink when the garment is cleaned and be durable enough to last the lifetime of the garment. The best performing lining fabrics like satin, crepe, crepe-backed satin, taffeta and lining twill give a silk or silk-like appearance to the inside of your garment. For additional warmth in colder climates use insulated fabrics as your lining.

Lining fabrics are often color-matched or blended with the garment. However, great drama can be added by using a well-chosen contrasting lining.

You should preshrink or test your lining fabric for shrinkage before cutting.

I have two different suitable lining fabrics that I will be using: 100% Cotton Hanes Drapery Lining Deluxe, $3.80/yd, 54″ wide from Fabric.com and 100% Silk, Cream/Pale Blush Striped Twill, $6.30/yd, 44″ wide from FabricMartFabrics.com

OTHER FABRICS AND NOTIONS

Lamb’s wool is a soft, highly napped fabric used to pad shoulder lines, or to give a soft roll to hems and facings. For more thickness, polyester fleece is used. For less bulk, double-faced outing flannel is recommended.

Winter coats to be worn in cold climates are sometimes interlinked for added warmth. Special fabrics for this purpose are sold in areas where coats are interlinked. Lamb’s wool, polyester fleece, and combination lining-interlining fabrics are good choices.

Color-matched nylon bias tape and seam binding may be needed. Shrink the seam binding before using by soaking in hot water, drying, then pressing.

Stay Tapes For Stability

Stay tape helps provide stability where seams may stretch out of shape, such as at shoulder, armhole and neckline seams. Stretching seams is a problem especially on knit fabrics.

Twill tape is tightly woven, usually a herringbone bone twill pattern, and is available in several widths from 1/4 inch to 3 inch. This tape is flat and can be used to finish straight-grain edges as a button placket, waistbands or reinforcement backing. It is usually 100% Cotton and if purchased in a natural color, should always be shrink tested before use.

According to traditional tailoring techniques, you should tape edges which will receive strain during wear and cleaning. Tape is especially needed along the front edge of your garment, around the neck seam, and on lapels because these areas have a tendency to pull or stretch out of shape. You may wish to tape other areas that might “give” with wear, such as shoulder or armhole seams, and fold lines of a seam pocket or vent openings.

Ribbon seam binding lends itself well to taping: it is thin, firmly woven, and usually preshrunk. Cotton twill tape, 1/4” wide, is often used; be sure it has been preshrunk.

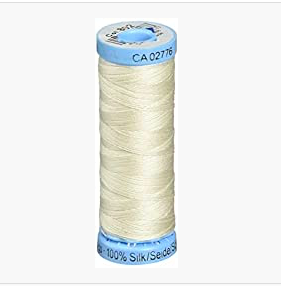

Thread

The correct thread is important to the success of any tailoring project. Silk is the best type of thread for any tailoring on wool, since silk is similar in chemical composition, elasticity, and strength to wool fabrics. Silk thread is advised for hand basting to avoid marks in the fabric when pressing over the basting. In some areas, silk thread is unavailable. Long-fibered spun polyester thread provides the best substitute.

On wool, silk buttonhole twist is used to sew on buttons, make thread loops, topstitching, and hand work buttonholes. Polyester buttonhole twist may be used on washable garments.

Thread should be color-matched to the wool, and also to the lining fabric if another color is used. To avoid running out of thread, it is a good idea to purchase several spools.

Summary of Purchased Fabrics and Notions for Custom Tailoring

- Outer Fashion Fabric, 6yds, 100% Wool Alabaster Fabric, $12.00/yd, 64″ wide from FabricMartFabrics.com – $72.00

- Hair Canvas Interfacing, 2yds, 60% Wool, 40% Goat Hair, $23.99/yd, 63″ wide from VogueFabricStore.com – $47.98

- Underlining, 6yds, Telio 100% Cotton Voile Ivory, $6.26/yd, 56″ wide from Fabric.com – $37.56

- Lining, 6yds, 100% Cotton Hanes Drapery Lining Deluxe, $3.80/yd, 54″ wide from Fabric.com – $22.80

- Lining #2, 5 yds, 100% Silk, Cream/Pale Blush Striped Twill, $6.30/yd, 44″ wide from FabricMartFabrics.com – $31.50

- Sleeve Heads, Needle Punch Soft Pocketing, $1.09/pair from Wawak.com – $1.09

- Twill Tape, 100% Cotton, 36 yards, 1/4″ wide, $3.95 from Wawak.com – $3.95

- Piping, 100% Natural Cotton Twisted Rope, 1/8″ wide, 328 ft., $11.79 from Amazon.com – $11.79

- Basting Thread, 100% Cotton, 2 cones, $5.50/ea. from BiasBespoke.com – $11.00

- Silk Sewing Thread, 5 spools, $5.49/ea. from Amazon.com – $27.45

- Topstitching Thread, Luminous All-Purpose, made in Poland, 2 spools, $3.25 from BiasBespoke.com – $6.50

- Waxed Carbon Tracing Paper, $5.25 from BiasBespoke.com – $5.25

- Total Cost for Fabrics and Notions – $278.87